Confluent Medical Technologies understands the importance of having a complete, competitive, and cost-effective manufacturable product. Which is why our product development team focuses on safety, budgets, design, and other considerations needed to successfully bring your finished medical device to market.

Balloon Catheter Rapid Prototyping

With over 20 years of experience, we provide you with a wide range of resources and facilities for prototype and development throughout your product development cycle — up to and including custom balloon catheter manufacturing — in just a matter of days.

- Raw materials: balloon/catheter tubing and tri-layer extrusion

- Parison stretching and die necking

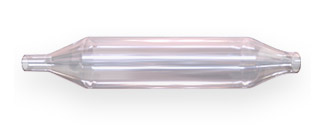

- Balloons: tapered, stepped, nonsymmetrical, Ø0 to 50 mm, and lengths up to 36 cm

- Fluting/wrapping/sheathing

- Marker band swaging

- Pad printing

- Balloon expandable stent placement

- Tube welding

- On-site machining (molds, water jackets, etc.)

- Braiding, coiling, and laminating

- Testing (destructive and non-destructive)

- High-pressure balloons

- Stent crimping and pillowing

Custom Balloon Catheters

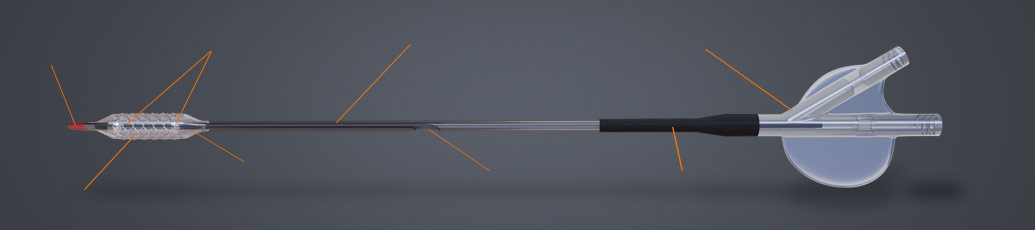

Partner with us for a complete solution to your custom catheter needs, from quick turn-around prototypes to high-volume production.

- Custom balloon mold blowing

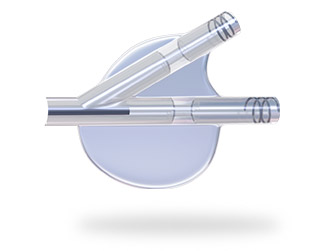

- Custom catheter shaft configurations with multiple shaft durometers and stiffness (liner/jacket material, braid/coil pattern, etc.)

- Ability to meet a variety of requirements: wall thickness, kink resistance, burst pressure, torque ability, push ability, flexibility, track ability, and radiopacity

- Able to hold tight ID and OD tolerances

- Catheters can include rapid exchange ports, marker bands, and atraumatic tip

Custom Medical Extrusion

Our dedicated extrusion team specializes in custom medical extrusions and can help you develop complex configurations that meet unique restrictions and specifications.

- Balloon tubing

- Single-lumen tubing

- Multi-lumen tubing

- Striping co-extrusion

- Tri-layer

- Bump tubing

- Lead tubing

- Custom welding sleeves

Reinforced Catheter Shaft Materials

Tasked with helping you identify the best catheter shaft materials, our engineers specialize in performing detailed analysis to help you develop the best prototypes at a fraction of the time and cost.

- Liner:

- PTFE

- Polyimide

- Pebax

- Nylon

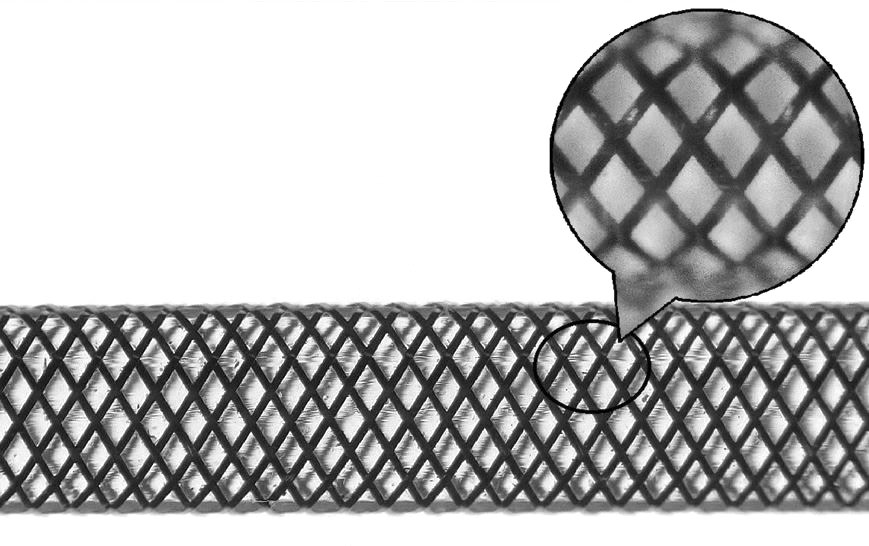

- Braid/Coil:

- Flat stainless steel wire

- Round stainless steel wire

- Nitinol wire

- Platinum wire

- Tungsten wire

- Non-metallic wire (plastic, textiles)

- Jacket:

- Polyurethane

- Pebax

- Nylon

Reinforced Catheter Shaft Options

Considering the initial performance of reinforced catheter shaft options is an absolute must. We understand this and will work to assure all design requirements meet the end needs of both the user and finished medical device.

- Coil:

- Clockwise pitch

- Counter-clockwise pitch

- Varying pitch in single shaft

- Braid:

- Regular braid pattern (one wire under two wires

- Full diamond pattern (two wires under two wires)

- Half diamond pattern (one wire under one wire)

- Tri-axial wires

- Varying PPI in single shaft