![]()

Interface Catheter Solutions specializes in complicated balloon and balloon catheter designs involving new materials for a multitude of minimally invasive applications throughout the body. Our team of diverse technology engineers pull together their deep understanding of balloon development and manufacturing to move balloon catheter designs from development prototypes to scaled production. Once the final design has been agreed upon, our team works to convert manufacturing variables into constants to ensure repeatability, high quality and high yields. Critical variables include environmental controls, parison forming, expansion ratios, hoop stresses, thermal profile across the length of the mold, extrusion lot-to-lot variations, etc. The accuracy and precision of raw materials, tooling and equipment all have a direct impact on the execution of a complex final product.

Interface has specific design and manufacturing expertise with balloons used in the following procedures: TAVR, Valvuloplasty, EVAR, TEVAR, Kyphoplasty, Sinuplasty and Esophageal Dilation.

Balloon Catheter Design Development Services:

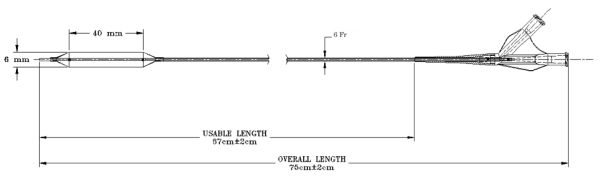

- Custom balloons per customer specs

- Diameters: 1 mm to 50 mm

- Lengths: Up to 320 mm

- Shapes: cylindrical, spherical, oval, conical, stepped, tapered, offset and more

- Semi-compliant, compliant & non-compliant materials: nylon, pebax®, polyurethane, PET, blended materials and more

- Uniform consistent wall thickness

- Increased burst pressures and improved fatigue

- Tight tolerance and defect-free balloons

- Tested and performance certified balloons

For more information, please contact info@interfaceusa.com.